- CNC ROUTER FEEDS AND SPEEDS FOR CUTTING 6063 ALUMINUM SOFTWARE

- CNC ROUTER FEEDS AND SPEEDS FOR CUTTING 6063 ALUMINUM TRIAL

- CNC ROUTER FEEDS AND SPEEDS FOR CUTTING 6063 ALUMINUM PLUS

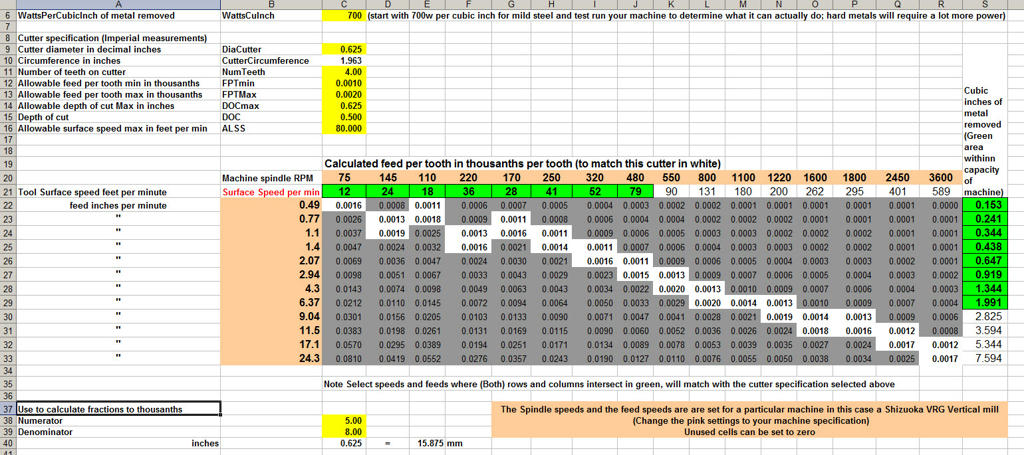

You will typically start off with the calculated feed rate. Typical chip thickness values for various size cuttersĮven though there are formulas for calculating feed rates you will find that optimum feed rate will be determined from experience. Higher power spindles will produce more torque thus allowing the machine to run at a variety of RPM’s (torque drops off as the RPM is reduced). The speeds and feeds chosen can be affected by the power of the spindle being used. If an extra long router bit is being used, the chip load should be decreased.įor most material that you will be cutting on a CNC router you will typically set the RPM between 1200, and adjust your feed rate to obtain the required results. When machining softer materials or using a stubby router bit the chip load can be increased. Therefore depending on the diameter of the tool, if the RPM and number of cutter edges stay the same chip load will increase with a larger diameter cutter, thus the feed rate will also increase. A larger cutter will be able to handle a larger chip load. Another factor that affects chip load is the diameter of the cutter.

CNC ROUTER FEEDS AND SPEEDS FOR CUTTING 6063 ALUMINUM PLUS

When calculating the feed rate for any material the chip load is therefore one of the most important factors to be taken into account because the chip load determines the amount of material that each tooth will remove, plus the load that each tooth will have to take. Therefore if chip load remains the same, and feed rate increases, either the RPM and or number of cutting edges must increase to maintain the recommended chip load.

The same applies to chip load if the recommended chip load is 0.1 mm/tooth the RPM, feed or number of cutting edges may go up or down to maintain the required chip load. If the number of cutting edges changes, however the feed rate will either increase or decrease depending on the whether the number goes up or down. If the RPM were increased to 24000 RPM the new feed rate would work out to be:īased on this equation, as RPM increases, feed rate will also increase if all other settings remain the same. If you are running at 18000 RPM using a 25mm cutter with two flutes, and a recommended chip load of 0.1 mm/tooth: For most materials there is a recommended chip load. We will now break down the relationship between the Feed rates, number of cutting edges, chip load and RPM. Z= RPM, the speed at which the cutter revolves in the spindle. T= chip load (chip per tooth) is the amount of material, which should be removed by each tooth of the cutter as it rotates and advances into the work. Most machine controllers allow you to adjust the feed rate while a program is running and by listening to the sound the cutter makes this can be a good way of optimizing the parameters.įeed rate is calculated using the following equation:

CNC ROUTER FEEDS AND SPEEDS FOR CUTTING 6063 ALUMINUM TRIAL

These often provide a good starting point but can usually be further improved through a small amount of trial and error. There are many resources available to help determine suitable settings for particular material / router bit combinations.

CNC ROUTER FEEDS AND SPEEDS FOR CUTTING 6063 ALUMINUM SOFTWARE

Feeds and speeds are usually all set in the programming software that is used to create the machine program. Chips will help by removing the heat produced in the cutting process thus increasing tool life and improving edge quality. One thing to remember is to make chips not dust.

This will help you find the best feed rate and RPM for any given tool and material. To obtain the optimum Chipload, you must consider these variables, along with the machine and materials you intend to cut. The feed rate used depends upon a variety of factors, including power and rigidity of the machine, rigidity of part hold-down, spindle horsepower, depth and width of cut, sharpness of cutting tool, design and type of cutter, and the material being cut. There are also several factors to be considered when choosing the proper RPM and feedrate. When material is machined the cutter must revolve at a specific RPM and feed at a specific feedrate to achieve the proper Chipload. Chipload can be defined as the size or thickness of the chip that is removed with each flute per revolution. One of the most important of these factors is the Chipload per Tooth (Cpt). There are certain parameters that must be considered, before setting up any file for cutting if you are to accomplish the finish and accuracy required.

0 kommentar(er)

0 kommentar(er)